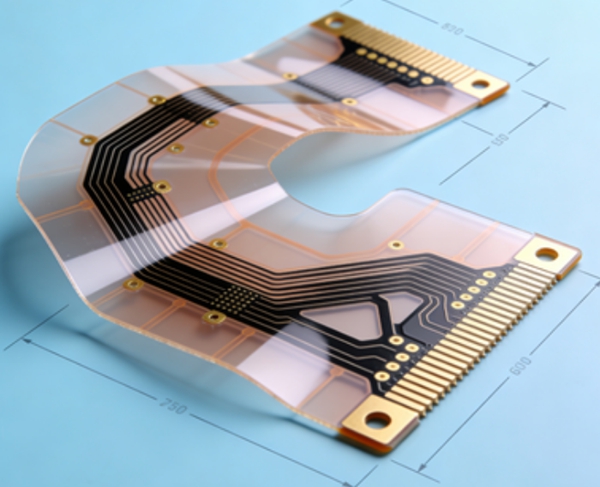

Flexible PCB layout design is fundamentally different from rigid PCB routing. Mechanical stress, bend behavior, and material limitations must be considered alongside electrical performance.

This article provides practical flexible PCB layout guidelines, focusing on trace routing, pad design, via usage, bend area rules, and manufacturability to ensure long-term reliability.

🔗 Part of the Flexible PCB Design Series

Flexible PCB Design: Materials, Layout, Reliability, and Manufacturing

Why Flexible PCB Layout Rules Are Different

In flexible PCBs, layout directly impacts:

- Mechanical fatigue life

- Bend reliability

- Assembly yield

- Long-term electrical stability

Poor layout choices often cause failures after deployment, not during initial testing.

Routing Rules for Flexible PCBs

Trace Orientation in Bend Areas

Best practices:

- Route traces perpendicular to the bend axis

- Avoid routing parallel to bend lines

- Stagger traces to prevent stress concentration

Parallel routing dramatically increases crack risk.

🔗 Mechanical background:

Bend Radius and Mechanical Reliability in Flexible PCB Design

Use Curved Traces Instead of Sharp Angles

- Avoid 90° corners

- Use arcs or smooth curves

- Gradual width transitions

Curved routing distributes strain more evenly during bending.

Trace Width and Spacing Considerations

Guidelines:

- Use wider traces where possible to reduce current density

- Avoid sudden width changes

- Maintain consistent spacing in bend regions

Uniform geometry improves both electrical and mechanical stability.

Pad and Land Pattern Design

Pad design in flex PCBs must minimize stress concentration.

Recommendations:

- Use rounded or teardrop-shaped pads

- Avoid sharp pad corners

- Keep pads out of dynamic bend areas

Pads near bend zones are common failure initiation points.

Via Usage in Flexible PCBs

General Via Guidelines

- Minimize vias in flex sections

- Avoid vias in dynamic bend areas

- Place vias in rigid or stiffened regions when possible

Vias introduce stiffness and stress risers.

Alternatives to Standard Vias

- Use stiffeners to support via regions

- Transition to rigid-flex designs for complex routing

Copper Balancing and Symmetry

Uneven copper distribution causes:

- Uneven bending behavior

- Localized stress concentration

Best practices:

- Balance copper density across layers

- Use symmetric layouts

- Avoid large copper pours in bend zones

Coverlay and Solder Mask Layout Rules

Coverlay design affects flexibility.

Guidelines:

- Avoid coverlay openings in bend areas

- Use gradual coverlay edge transitions

- Ensure adequate clearance around pads

Coverlay edges can act as mechanical stress points.

Component Placement Considerations

Placement rules:

- Keep components out of flexing areas

- Place components on neutral or rigid sections

- Avoid heavy components on flex arms

Component-induced stress is a major reliability risk.

Designing for Assembly and Manufacturing

Layout should account for:

- Pick-and-place constraints

- Connector insertion forces

- Assembly tooling

Early DFM review with the flex PCB manufacturer is critical.

Best Practices Summary

To improve flexible PCB reliability through layout:

- Route traces perpendicular to bend lines

- Use curved routing and smooth transitions

- Avoid vias and pads in bend areas

- Balance copper distribution

- Coordinate layout with mechanical constraints

Conclusion

Flexible PCB layout design directly determines mechanical reliability and product lifespan. By applying disciplined routing, pad design, and placement rules, engineers can significantly reduce flex-related failures.

This article completes the design execution layer of the Flexible PCB knowledge cluster.

FAQ – Flexible PCB Layout Design

A: No. Flex PCBs require routing rules optimized for bending and mechanical stress.

A: This orientation minimizes strain on copper during bending.

A: No, but they should be avoided in dynamic bend areas.

A: Only carefully. Large pours reduce flexibility and may cause stress concentration.

A: Only in static flex areas with sufficient mechanical support.

A: At the layout planning stage—waiting until routing is complete is too late.