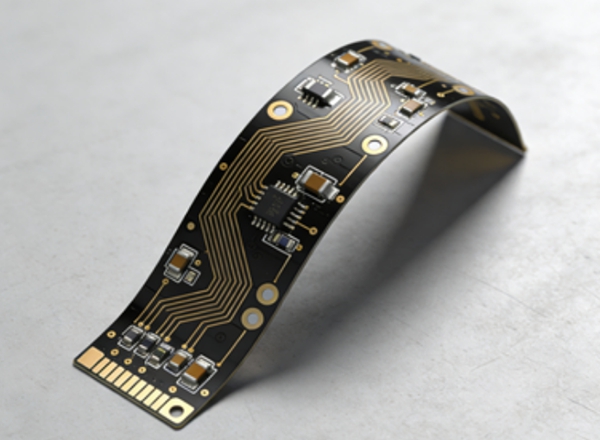

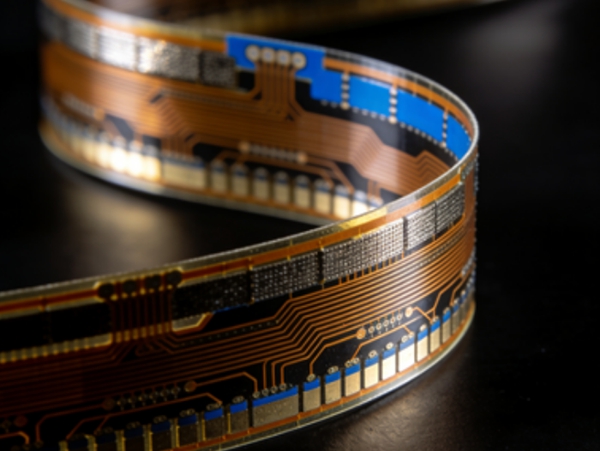

Flexible PCB manufacturing introduces challenges not found in rigid board fabrication. Thin materials, adhesive systems, and tight mechanical tolerances significantly affect yield, cost, and reliability.

This article focuses on flexible PCB manufacturing considerations and yield optimization, helping designers understand how early design decisions influence fabrication success and mass production stability.

🔗 Part of the Flexible PCB Design Series

Flexible PCB Design: Materials, Layout, Reliability, and Manufacturing

Why Flexible PCB Yield Is More Sensitive

Compared to rigid PCBs, flexible circuits are more susceptible to:

- Material handling damage

- Dimensional instability

- Registration errors

- Coverlay misalignment

Small design oversights can lead to disproportionate yield loss.

Material Selection and Manufacturing Impact

Thin Dielectrics and Handling Risk

Ultra-thin PI films improve flexibility but:

- Increase wrinkle risk

- Complicate lamination

- Reduce panel handling stability

Manufacturing-friendly thickness selection improves yield.

Adhesive Systems and Lamination Control

Adhesive-based laminates require:

- Tight lamination pressure control

- Uniform adhesive flow

- Controlled curing profiles

Adhesiveless laminates simplify processing but increase material cost.

Panelization and Tooling Design

Panel design directly affects yield.

Best practices:

- Use carrier panels for thin flex circuits

- Design breakaway tabs carefully

- Avoid stress concentration at depaneling points

Poor panelization is a common root cause of flex PCB scrap.

Coverlay Processing and Alignment

Coverlay challenges include:

- Registration accuracy

- Adhesive squeeze-out

- Edge lifting

Design recommendations:

- Increase coverlay-to-pad clearance

- Avoid dense openings near bend zones

- Maintain consistent coverlay geometry

Drilling, Vias, and Plating Challenges

Key considerations:

- Flex materials deform during drilling

- Via quality is sensitive to plating control

- Through vias reduce flexibility

Whenever possible, place vias in rigid or stiffened regions.

Surface Finish Selection

Surface finish affects both yield and assembly.

Common options:

- ENIG: stable but adds stiffness

- OSP: flexible-friendly but limited shelf life

- Immersion silver: good balance for flex

Finish selection should align with assembly and mechanical requirements.

Design for Assembly (DFA) in Flexible PCBs

Assembly risks include:

- Component shift during reflow

- Connector insertion damage

- Warpage

Mitigation strategies:

- Use stiffeners for component zones

- Optimize pad geometry

- Coordinate assembly profiles early

Yield-Oriented Design Checklist

To maximize manufacturing yield:

- Avoid ultra-thin constructions unless required

- Minimize vias in flex sections

- Design robust panelization

- Coordinate coverlay design with fabricator

- Conduct DFM reviews early

Validation and Pilot Production

Before mass production:

- Run pilot builds

- Review yield data

- Adjust stackup or layout as needed

Early validation saves cost and time.

Conclusion

Flexible PCB manufacturing yield is heavily influenced by design decisions made long before fabrication begins. By understanding manufacturing constraints and designing with yield in mind, engineers can significantly improve production stability and reduce total cost.

This article completes the manufacturing layer of the Flexible PCB Design content cluster.

Flexible PCB Manufacturing & Yield FAQ

A: Thin materials and mechanical sensitivity make flex PCBs more vulnerable to handling and processing variation.

A: They simplify some steps but require tighter process control and higher material cost.

A: Panel handling damage and coverlay misalignment are common causes.

A: No. Most yield problems originate from early design decisions.

A: Stiffeners are recommended in component and connector areas.

A: Ideally during stackup and layout planning stages.