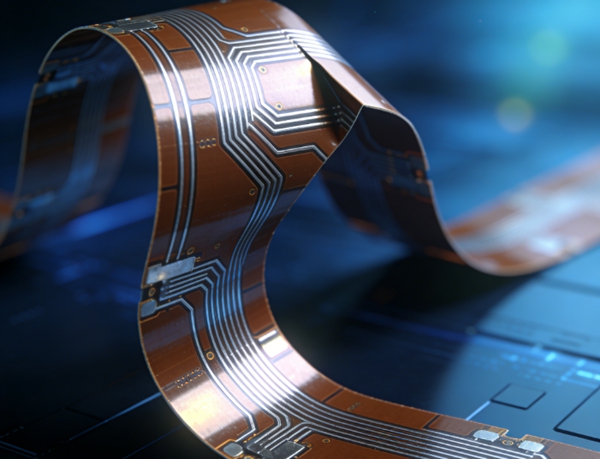

Material selection and stackup design define the electrical and mechanical behavior of flexible PCBs. Unlike rigid boards, flexible circuits must balance electrical performance, mechanical reliability, and manufacturability under repeated bending and assembly stress.

This article explains flexible PCB materials and stackup design, focusing on polyimide dielectrics, copper types, adhesive systems, and stackup strategies that improve flexibility and long-term reliability.

🔗 Part of the Flexible PCB Design Series

Flexible PCB Design: Materials, Layout, Reliability, and Manufacturing

Core Materials Used in Flexible PCBs

Polyimide (PI) Dielectric

Polyimide is the most widely used dielectric in flexible PCBs due to:

- Excellent thermal stability

- High mechanical flexibility

- Stable electrical properties

PI thickness selection affects both bend radius and impedance control.

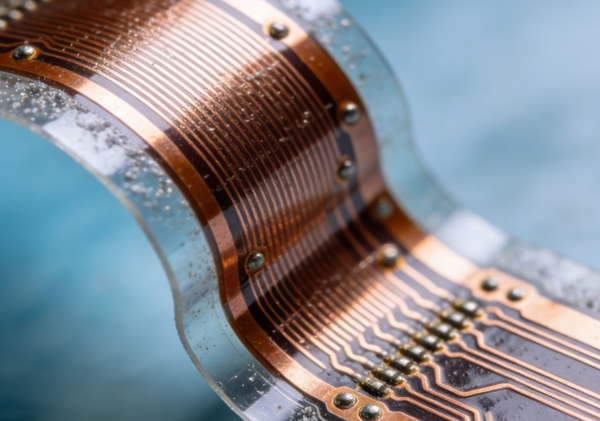

Copper Types: Rolled-Annealed vs Electro-Deposited

Copper selection is a major reliability driver.

- Rolled-Annealed (RA) Copper

- Superior ductility

- Preferred for dynamic bending

- Electro-Deposited (ED) Copper

- Lower cost

- Suitable for static applications

Dynamic flex designs should strongly favor RA copper.

Adhesive Systems and Adhesiveless Laminates

Adhesive-Based Constructions

- Use acrylic or epoxy adhesives

- Lower cost

- Reduced flexibility and higher stress concentration

Adhesiveless Laminates

- Copper bonded directly to PI

- Improved flexibility

- Better mechanical reliability

- Higher cost but preferred for demanding applications

Material construction choice directly impacts bend life.

Coverlay Materials and Design Considerations

Coverlays protect copper and provide insulation.

Best practices:

- Use PI-based coverlays for flexibility

- Avoid coverlay openings in bend areas

- Ensure smooth transitions near pads

Coverlay thickness adds to total flex thickness and must be included in bend calculations.

Flexible PCB Stackup Structures

Single-Layer Flex

- Simplest structure

- Best flexibility

- Limited routing capability

Double-Layer Flex

- Increased routing density

- Requires careful copper balance

- Neutral axis planning becomes critical

Multilayer Flexible PCB

- Used when routing density is high

- Reduced flexibility

- Requires strict stackup symmetry

🔗 Mechanical implications:

Bend Radius and Mechanical Reliability in Flexible PCB Design

Stackup Design and the Neutral Axis

Placing copper layers near the neutral axis reduces mechanical strain during bending.

Key guidelines:

- Use symmetric stackups

- Minimize copper thickness

- Avoid copper on outermost layers in bend zones

Stackup design is the most effective lever for improving mechanical reliability.

Electrical Performance vs Mechanical Flexibility

Trade-offs are inevitable:

- Thicker dielectrics improve impedance control

- Thinner constructions improve flexibility

- Copper thickness affects loss and reliability

Designers must prioritize based on application requirements.

Material Selection and Manufacturability

Material choices affect:

- Fabrication yield

- Lead time

- Supplier availability

Early collaboration with flex PCB manufacturers helps avoid unrealistic stackups.

Best Practices Summary

- Use polyimide dielectrics for flexibility

- Prefer RA copper for dynamic bending

- Consider adhesiveless laminates for reliability

- Design symmetric stackups around the neutral axis

- Balance electrical and mechanical requirements

Conclusion

Flexible PCB materials and stackup design are foundational to both electrical performance and mechanical reliability. By selecting appropriate materials and designing stackups with bending behavior in mind, engineers can significantly extend flex PCB lifetime and reduce failure risk.

This article provides the material science foundation for reliable flexible PCB design.

FAQ – Flexible PCB Materials and Stackup

A: Polyimide offers excellent flexibility, thermal stability, and reliable electrical performance.

A: RA copper should be used in dynamic bending applications where mechanical fatigue is a concern.

A: They offer better reliability but at higher cost; selection depends on application demands.

A: Yes. Symmetric stackups reduce mechanical stress and improve reliability.

A: Material thickness, copper type, and adhesive systems all influence minimum bend radius.

A: No. FR-4 lacks the flexibility required for bending applications.