High Density Interconnect (HDI) PCB design enables compact, high-performance electronic products by dramatically increasing routing density and interconnection capability. HDI technology is widely used in smartphones, medical devices, automotive electronics, and advanced computing systems.

This article provides a comprehensive overview of HDI PCB design, explaining key technologies, benefits, applications, and when HDI is the right choice over conventional PCB designs.

🔗 Part of the HDI PCB Design Series

HDI PCB Design: Technology, Stackup, Routing, and Manufacturing

What Is an HDI PCB?

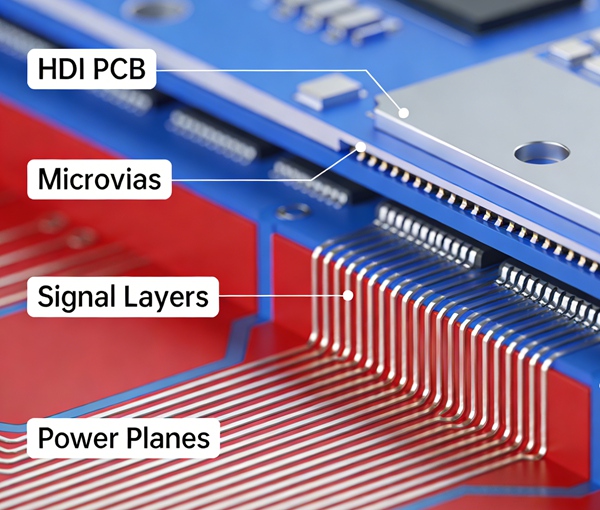

An HDI PCB is characterized by:

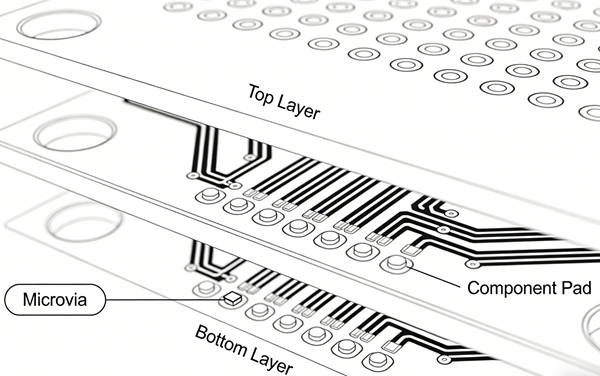

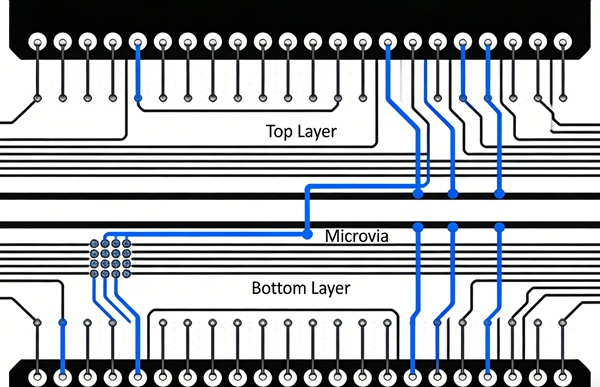

- Microvias (laser-drilled vias ≤150 µm)

- Blind and buried vias

- Fine line / fine spacing routing

- Sequential lamination processes

HDI technology increases interconnection density without increasing board size.

Key Features of HDI PCB Technology

Microvias

- Laser-drilled

- Short via depth

- Lower parasitic inductance

Microvias enable high-speed and high-density signal routing.

Blind and Buried Vias

- Blind vias: connect outer to inner layers

- Buried vias: connect inner layers only

They free surface routing space and improve signal integrity.

Sequential Lamination

HDI PCBs are built in stages, allowing complex layer interconnections not possible in standard PCBs.

Benefits of HDI PCB Design

HDI PCBs offer:

- Smaller board size

- Higher routing density

- Improved electrical performance

- Better signal integrity

- Reduced layer count in some designs

These benefits are critical for compact and high-speed systems.

Typical Applications of HDI PCBs

HDI technology is commonly used in:

- Smartphones and tablets

- Wearable electronics

- Medical devices

- Automotive ADAS systems

- High-speed computing modules

When Should You Choose HDI PCB Design?

HDI is suitable when:

- BGA pitch ≤ 0.8 mm

- Routing congestion limits standard PCB designs

- Signal integrity requirements are strict

- Board size must be minimized

HDI is not always the lowest-cost option, but often the only viable solution.

HDI PCB vs Conventional PCB

| Aspect | HDI PCB | Standard PCB |

|---|---|---|

| Via size | Microvia | Mechanical via |

| Routing density | Very high | Limited |

| Board size | Smaller | Larger |

| Manufacturing complexity | High | Lower |

Design Considerations Before Using HDI

Engineers must consider:

- Fabrication capability

- Cost impact

- Yield risk

- DFM coordination

Early supplier involvement is critical for HDI success.

Conclusion

HDI PCB design enables the next generation of compact, high-performance electronics. Understanding HDI technology fundamentals helps engineers decide when and how to adopt HDI effectively.

This article establishes the technical foundation for the HDI PCB Design content cluster.

FAQ – HDI PCB Design Overview

A: HDI stands for High Density Interconnect, referring to PCB designs using microvias and fine routing to increase density.

A: No. HDI is widely used in medical, automotive, and industrial systems.

A: Often yes, but the primary benefit is routing density, not size alone.

A: Upfront cost is higher, but system-level cost may be reduced.

A: Yes. Shorter vias and optimized routing improve signal integrity.