Hansphere provides PCB assembly services for customers in Saudi Arabia, supporting prototype builds, pilot runs, and small-to-medium production volumes. Our assembly process is closely coordinated with PCB design and manufacturing to help ensure reliable results and consistent product quality.

Rather than treating assembly as a standalone operation, we integrate engineering review, component handling, and inspection into a structured assembly workflow.

PCB Assembly Support for Saudi Arabia Projects

PCB assembly for Saudi Arabia projects often requires accuracy, clear documentation, and controlled processes. Hansphere supports these requirements through an assembly approach that emphasizes preparation, verification, and quality control.

Our PCB assembly services are suitable for customers who require:

- Reliable assembly for prototypes and production builds

- Clear coordination between design, manufacturing, and assembly

- Reduced assembly-related defects and rework

- Engineering support throughout the assembly process

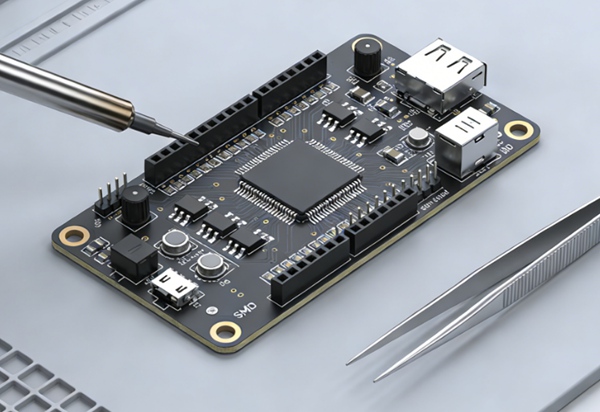

PCB Assembly Capabilities

Assembly Types

Hansphere supports multiple PCB assembly technologies, including:

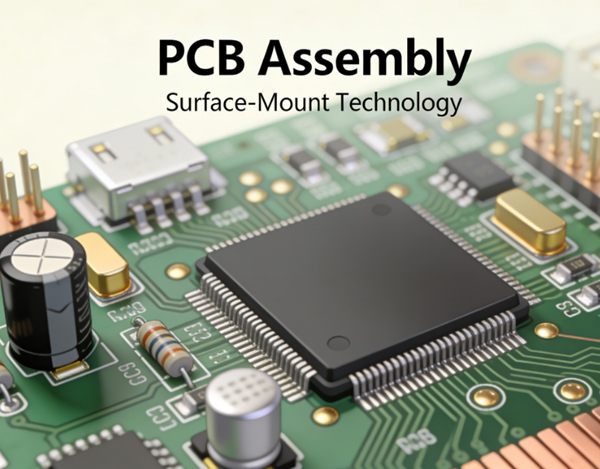

- SMT (Surface Mount Technology) assembly

- THT (Through-Hole Technology) assembly

- Mixed-technology assembly

These capabilities allow us to support a wide range of PCB designs and applications.PCB design services in Saudi Arabia

Production Scope

Our PCB assembly services support:

- Prototype assembly

- Pilot production runs

- Small-to-medium volume production

Assembly processes are selected based on design complexity, component requirements, and production volume.

Component Handling and BOM Verification

Component handling is a critical part of reliable PCB assembly. Hansphere follows structured procedures to help reduce placement errors and component-related issues.

Our component support includes:

- BOM verification before assembly

- Support for customer-supplied components

- Partial component sourcing when required

- Verification of component footprints and polarity

These steps help improve first-pass assembly success.

Inspection and Testing

Inspection and testing are integrated into the PCB assembly workflow. Depending on project requirements, these activities may include:

- Visual inspection

- Automated Optical Inspection (AOI)

- Functional testing based on customer specifications

Inspection results are reviewed before assemblies are approved for delivery or further integration.

How to Start a PCB Assembly Project in Saudi Arabia

PCB assembly projects with Hansphere follow a clear and structured process: PCB manufacturing services in Saudi Arabia

- Step 1: Provide PCB design files, BOM, and assembly requirements

- Step 2: Engineering review and assembly feasibility check

- Step 3: Component preparation and assembly planning

- Step 4: PCB assembly and inspection

- Step 5: Testing (if required) and delivery

This process helps ensure transparency and alignment throughout the assembly stage.

Frequently Asked Questions

A: Yes. We support PCB assembly for boards manufactured by Hansphere as well as boards provided by customers.

A: We support prototype builds, pilot runs, and small-to-medium production volumes.

A: Yes. Functional testing can be supported based on customer requirements.

A: Yes. PCB assembly can be seamlessly integrated with our PCB design and manufacturing services.

Work with Hansphere

Hansphere works with customers in Saudi Arabia as a PCB assembly partner focused on accuracy, process control, and reliable delivery.

Our goal is to support consistent PCB assembly results that integrate smoothly with upstream design and manufacturing processes.