Hansphere provides reliable PCB manufacturing services for customers in Saudi Arabia, supporting projects from prototype builds to small and medium production volumes. Our manufacturing process is closely aligned with engineering and quality control requirements to ensure consistent and repeatable results.

Rather than treating fabrication as an isolated step, we focus on manufacturing processes that are integrated with PCB design and assembly considerations.

Manufacturing Support for Saudi Arabia Projects

PCB manufacturing for Saudi Arabia projects often requires stable quality, clear documentation, and predictable delivery. Hansphere supports these requirements through structured manufacturing workflows and close coordination between engineering and production teams.

Our manufacturing services are suitable for customers who require:

- Consistent PCB quality across builds

- Clear process control and inspection

- Smooth transition from design to assembly

- Support for both new and existing PCB designs

PCB Manufacturing Capabilities

Supported PCB Types

Hansphere supports a wide range of PCB technologies, including:

These capabilities allow us to support diverse applications and design requirements.

Technical Manufacturing Capabilities

Our PCB manufacturing services include support for:

- Multilayer PCB fabrication

- Controlled impedance designs

- HDI structures

- Fine-pitch and high-density layouts

Manufacturing parameters are reviewed during the design stage to reduce the risk of late-stage changes. PCB design services in Saudi Arabia

Materials and Stack-Up Management

Material selection and stack-up design are important factors in PCB reliability and manufacturability. Hansphere works with customers to confirm materials and layer structures before production begins.

Supported material options may include:

- Standard FR-4 materials

- High-Tg materials for improved thermal performance

- Special materials based on application requirements

Stack-up details are documented clearly to ensure repeatability across production runs.

Quality Control and Inspection

Quality control is an integral part of the PCB manufacturing process. Depending on project requirements, inspection and testing may include:

- Electrical testing

- Automated Optical Inspection (AOI)

- Visual inspection

- Process documentation and material traceability

These measures help ensure that manufactured PCBs meet design and quality expectations before PCB assembly services in Saudi Arabia

How to Start a PCB Manufacturing Project in Saudi Arabia

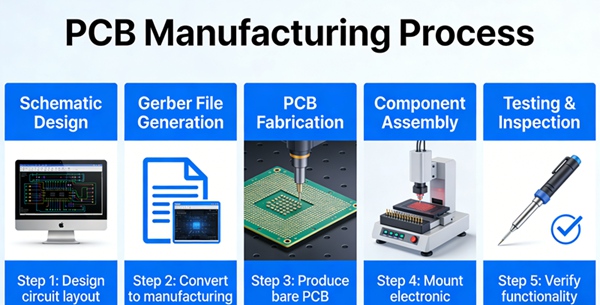

PCB manufacturing projects with Hansphere follow a clear and structured process:

- Step 1: Provide Gerber files, ODB++ data, stack-up details, and manufacturing notes

- Step 2: Engineering and manufacturability review

- Step 3: Confirmation of materials, specifications, and production parameters

- Step 4: PCB fabrication and inspection

- Step 5: Delivery or handover to PCB assembly

This process helps ensure transparency and alignment throughout manufacturing.

Frequently Asked Questions

A: Yes. Hansphere supports PCB manufacturing for designs provided by customers or third-party designers.

A: We support prototype builds as well as small-to-medium production volumes.

A: Quality is maintained through defined manufacturing processes, inspection steps, and documentation control.

A: Yes. PCB manufacturing can be seamlessly combined with our PCB assembly services.

Work with Hansphere

Hansphere works with customers in Saudi Arabia as a PCB manufacturing partner focused on quality, process stability, and clear communication.

Our goal is to support reliable PCB fabrication that integrates smoothly with design and assembly requirements.