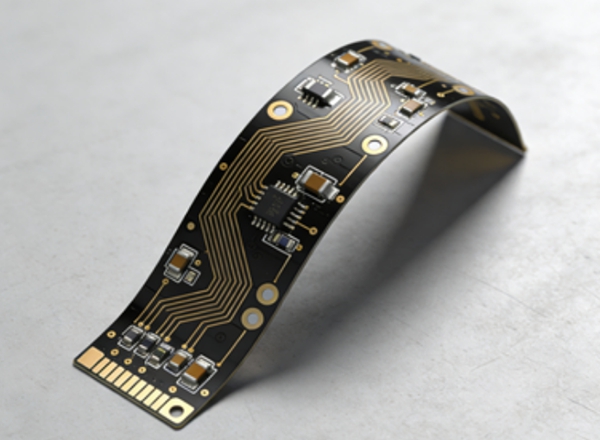

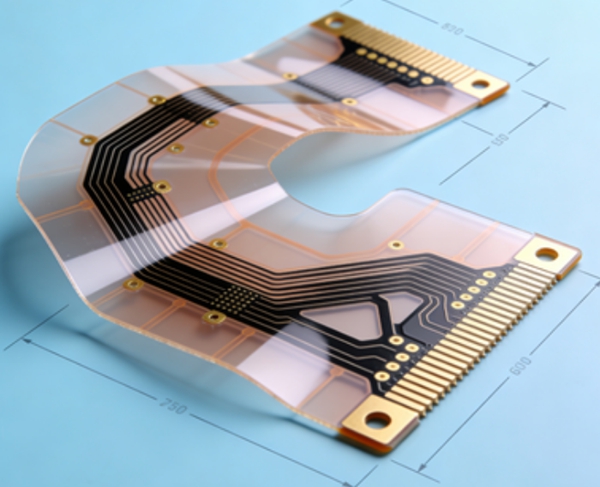

Rigid-flex PCBs combine rigid boards and flexible circuits into a single integrated structure. This approach eliminates connectors, reduces assembly complexity, and improves reliability—but significantly increases design and manufacturing complexity.

This article covers rigid-flex PCB design guidelines, focusing on stackup transitions, material selection, layout rules, mechanical reliability, and manufacturing constraints to help engineers avoid common failures.

🔗 Part of the Flexible PCB Design Series

Flexible PCB Design: Materials, Layout, Reliability, and Manufacturing

What Makes Rigid-Flex PCB Design Challenging

Rigid-flex designs must simultaneously satisfy:

- Rigid PCB electrical performance

- Flexible PCB mechanical reliability

- Complex lamination and fabrication processes

Failures often occur at rigid-to-flex transition zones, making them the most critical design areas.

Rigid-Flex Stackup Architecture

Common Rigid-Flex Structures

- Rigid sections using FR-4

- Flex sections using polyimide

- Copper layers continuous through rigid and flex regions

Key challenge: managing thickness and stiffness transitions.

Layer Transitions and Step-Down Design

Best practices:

- Gradually remove rigid layers toward flex regions

- Avoid abrupt copper layer termination

- Use smooth layer step-down geometries

Abrupt transitions create stress concentration and delamination risk.

Material Selection for Rigid-Flex PCBs

Dielectric Materials

- FR-4 for rigid sections

- Polyimide for flex sections

Material CTE mismatch must be carefully managed.

Copper Selection

- RA copper preferred in flex regions

- ED copper acceptable in rigid sections

Copper continuity must be planned to minimize mechanical stress.

Layout Rules at Rigid-Flex Transitions

Transition zones require special layout discipline:

- Avoid vias near transition edges

- Route traces perpendicular to bend lines

- Use curved routing in flex regions

- Keep copper balanced across layers

🔗 Related layout rules:

Flexible PCB Layout Guidelines and Best Practices

Bend Radius and Mechanical Reliability

Rigid-flex designs often include dynamic or semi-static bending.

Key rules:

- Define bend zones early

- Apply conservative bend radius rules

- Keep components out of bend areas

🔗 Mechanical foundation:

Bend Radius and Mechanical Reliability in Flexible PCB Design

Manufacturing Considerations for Rigid-Flex PCBs

Rigid-flex fabrication introduces additional risks:

- Complex lamination cycles

- Registration challenges

- Higher scrap rates

Designers should:

- Simplify stackups where possible

- Avoid unnecessary layer count

- Involve manufacturers early

🔗 Yield perspective:

Flexible PCB Manufacturing Considerations and Yield Optimization

Assembly and Reliability Risks

Common issues include:

- Cracking at rigid-flex interfaces

- Delamination during reflow

- Connector stress transfer

Mitigation strategies:

- Use stiffeners strategically

- Control assembly profiles

- Validate with mechanical testing

Testing and Validation

Recommended validation methods:

- Bend cycle testing

- Cross-section analysis

- Thermal cycling

Testing should reflect real-world use cases.

Best Practices Summary

To design reliable rigid-flex PCBs:

- Plan rigid-flex architecture early

- Use gradual layer transitions

- Optimize materials for each region

- Apply flex layout rules strictly

- Validate with realistic testing

Conclusion

Rigid-flex PCB design offers significant system-level advantages but demands disciplined design and manufacturing coordination. By following proven rigid-flex design guidelines, engineers can achieve high reliability while reducing assembly complexity and long-term risk.

This article completes the structural integration layer of the Flexible PCB Design knowledge cluster.

FAQ – Rigid-Flex PCB Design

A: The rigid-to-flex transition zone due to stress concentration.

A: Yes, but only if designed for dynamic bending with appropriate materials and bend radius.

A: Upfront cost is higher, but total system cost may be lower due to reduced connectors and assembly steps.

A: Generally no, except in static flex areas with sufficient support.

A: During initial stackup and architecture planning.

A: No. Flex-specific and transition-zone rules must be applied.